Investment Casting

Company Overview

.png)

Locke-Brothers partners with Shelmet Precision Casting Company who specialize in investment castings since 1960. Shelmet is a leading American investment casting manufacturer. Often referred to as the lost wax method, Shelmet has internally refined the investment casting process and specializes in short-to-medium-run orders. Shelmet is a non-union, family-owned shop that has a strong emphasis on customer satisfaction.

Capabilities

WHAT WE DO

Cast in Features You Can't Machine

LEARN MORE

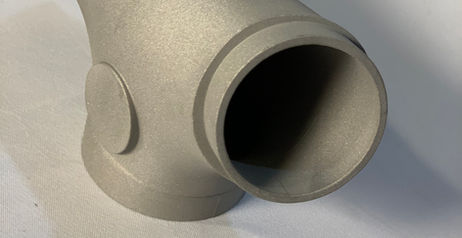

Shelmet specializes in parts that fit into a 6” x 6“ x 6” cube; they pour stainless steels, a wide variety of carbon steels, cobalt and aluminum. Their niche is low to medium volume investment castings. Investment castings are near net shape which help minimize costly machine operations.

Shelmet has the ability to produce rapid prototypes via 3D wax patterns efficiently. Shelmet can produce an investment casting tool within four to six weeks.

Together with Shelmet, Locke-Brothers will review your design and offer suggestions to improve manufacturability, part design which can reduce costs and improve quality. Investment castings are near net shape which help minimize costly machine operations.

Example Parts

-

Motor Box Housings

-

Sensors

-

Brackets

-

Enclosures

-

Covers

-

Medical Devices

-

Motor Cycle Parts

Value Added Processes

Machining

Brazing

Heat Treating

Cosmetic Finishing

Spotlight: D2P 2022

Quality

Shelmet takes great pride in their investment castings by offering a finish none other in the industry. Their process ensures that your parts can go straight from the foundry to your assembly line.

Shelmet’s investment casting experts offer you an added layer of confidence from the initial concept to finished parts delivered to your door. Each step of the process is verified for quality and geometry before moving on. Critical dimensions are checked to ensure customer satisfaction.

Shelmet has a ISO Quality Certification to maintain verifiable and consistent production quality on each casting project.

Customer Satisfaction

Shelmet has been around for 60+ years, and continually invests in technology to improve their investment casting capabilities. In 2019, Shelmet purchased a furnace for melting aluminum just to satisfy one of their customer's needs.

On-time delivery of 98% while their casting specialists maintain a hands-on and comprehensive monitoring of every order.

Shelmet cares about its customers and employees equally. Their average employee has worked at Shelmet for 15+ years, enabling team and customer familiarity.

We’ve been working with Shelmet Precision Casting for over 30 years. I first started working with Gary Oliver, Vice President Shelmet, back in 1990, and I still work with him today. At Locke-Brothers, we build relationships that last.

-Robb Tausend