Company Overview

In 2020 Locke-Brothers partnered with Production Castings, Inc., to supply Aluminum and Zinc Die Castings. We are excited for this newly created relationship and the ability to expand our casting offerings.

Production Castings, Inc. was founded 45+ years ago, and is centrally located near St. Louis, Missouri. Production Castings has grown to be a leading supplier of zinc and aluminum die castings to a variety of industries throughout North America, Central America, Europe and Asia.

Production Castings and Locke-Brothers offer more than just die castings. We offer many value-added services such as machining, finishing, and sub-assemblies - all located on one campus.

Locke-Brothers began this partnership with Production Castings due to their remarkable engineering support, practice of Design for Manufacturing (DFM), complete in-house capabilities, and their commitment to premier customer service.

Capabilities

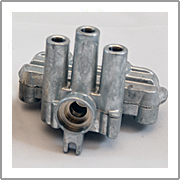

With 40+ die cast machines ranging in size from 5 tons to 650 tons, Production Castings has the ability and experience to produce everything from high speed miniature zinc castings to large aluminum castings weighing up to 8 pounds. Production Castings utilizes some of the latest shot monitoring equipment and robotics to achieve unsurpassed quality and productivity.

Die Castings

Aluminum Die Casting

Production Castings Cold Chamber machines range from 400-600 Tons; they can produce an aluminum casting that weights up to 8 pounds. These machines are equipped with the latest shot monitoring systems as well as robotic automation.

Zinc Die Casting

Production Castings Hot Chamber machines range from 5 tons to 650 tons. They utilize both high-speed miniature zinc casting machines as well as larger conventional machines. This allows for the selection of the best machine for the part.

Machining

Production Castings has its own precision machining department. They are capable of machining simple operations like drilling and tapping as well as more complex machining. Whatever your requirements may be, we can support you.

Painting

Production Castings has its own in-house powder paint line. The line has two paint booths, and the entire system has been designed specifically for zinc and aluminium die casting.

Example Parts

-

Electric Motor & Gear

-

Housings

-

Lighting Fixtures

-

Firearm Components

-

Power Transmission Components

-

Industrial Tools

-

Pneumatics

-

Oil and Gas Components

-

Appliances

-

Medical Devices

Value Added Processes

Plating

Assembly

Cast Inserts

Wet Paint

Spotlight: D2P 2022

Quality

As a leader in their field, Production Castings has earned several quality and service awards, including 2005 & 2006 North American Die Casting Associations award for “excellence in aluminum die casting” and “excellence in zinc die casting.”

Production Castings has also been named Metal Caster of the Year by the American Foundry Society. Additionally, Production Castings was awarded the National “Outstanding” safety award for 15 consecitive years.

Production Castings systems are certified to ISO 9001:2015 by NSF International Strategic Registrations, ANAB accredited, and a member of IAF. They focus on a safe working environment with quality production.

Customer Satisfaction

Production Castings maintains customer production needs as their number one priority, with a strong commitment to quality, safety, and timely deliveries. They focus on efficient production methods to guarantee timely customer delivery and satisfactory quality standards.

Locke-Brothers and Production Castings believe in establishing strong and lasting partnerships with all of their customers. We believe that “Quality is our customers’ satisfaction.” We offer some of the highest service levels in the industry today.

With Locke-Brothers and Production Castings you get:

-

Innovations and solutions - We make things happen. We won’t accept “it can’t be done” as an answer.

-

Integrity - We protect your intellectual property and you can count on us to deliver quality castings at a fair price.

-

Accessibility - Locke-Brothers is happy to take you to Production Casting’s facility to meet their team.

-

Reliability - We will not let you down. Together we will get the job done right from design to delivery.

"Production Castings is vertically integrated, from in-house tool builds to machining and painting your parts. Production Castings does it best."

-Ryan O'Leary